Monday, November 11, 2024

How to Build a Pole Barn with a Custom Foundation for Stability

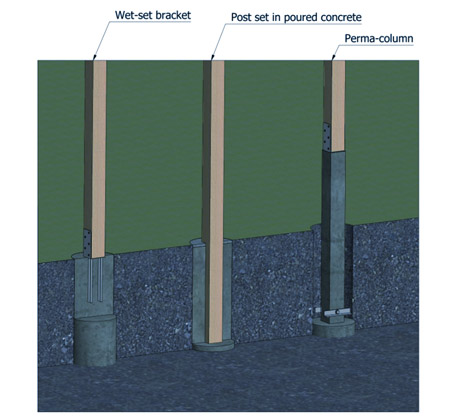

A pole barn, with its rustic charm and adaptable design, offers a versatile solution for a range of purposes, from workshops and garages to livestock shelters and storage facilities. However, achieving enduring stability and functionality requires careful consideration of the foundation. While traditional concrete piers or poured concrete slabs are common choices, exploring custom foundation options can elevate your pole barn to new heights of durability and longevity.

Understanding the Need for a Robust Foundation

Pole barns, unlike conventional structures with continuous wall supports, rely heavily on their foundation posts to bear the weight of the building and withstand environmental pressures. Neglecting the foundation can lead to a cascade of problems, including:

Structural Instability: Uneven settling or weak foundation posts can cause the barn to sag, crack, or even collapse.

Water Damage: Inadequate foundation drainage can lead to moisture intrusion, compromising the wood framing and creating an environment conducive to mold and rot.

Pest Infestations: Gaps or weaknesses in the foundation can provide entry points for rodents, insects, and other pests, jeopardizing the structural integrity and hygiene of the building.

Exploring Custom Foundation Solutions for Unwavering Stability

Custom foundation design allows you to tailor the structure to your specific site conditions and building needs. Here, we delve into the intricacies of different foundation types:

1. Engineered Pier Foundation:

Description: This approach involves installing deep, reinforced concrete piers that extend below the frost line, ensuring stability even in regions with freezing temperatures.

Advantages:

Superior load-bearing capacity.

Reduced susceptibility to frost heave.

Adaptable to challenging terrain.

Considerations:

Higher initial costs compared to simpler pier systems.

Requires specialized equipment for installation.

2. Insulated Concrete Forms (ICFs):

Description: ICFs are reusable plastic forms filled with concrete to create monolithic walls that provide exceptional insulation and strength.

Advantages:

Energy-efficient building envelope.

Enhanced resistance to moisture and pests.

Exceptional structural integrity.

Considerations:

Higher material and labor costs.

Requires specialized installation techniques.

3. Helical Pier Foundation:

Description: Helical piers are large-diameter screws that are driven into the ground, providing strong anchorage.

Advantages:

Cost-effective and efficient installation.

Minimal disruption to the surrounding landscape.

Suitable for challenging soil conditions, including clay and bedrock.

Considerations:

May not be ideal for extremely heavy structures.

Potential for soil disturbance during installation.

4. Combination Foundation Systems:

Description: Integrating different foundation types to maximize stability and cost-effectiveness. For instance, using helical piers for areas with loose soil and ICFs for sections requiring greater insulation.

Advantages:

Customized solution for unique site conditions.

Optimizes cost and performance based on specific needs.

Considerations:

Requires meticulous planning and coordination.

May necessitate specialized expertise for integration.

Steps to Design and Construct a Custom Foundation:

1. Site Assessment and Soil Testing: Conduct a thorough site analysis, including soil testing, to understand the bearing capacity, frost depth, and water table levels. This information is crucial for selecting the most appropriate foundation type.

2. Professional Engineering Consultation: Collaborate with a structural engineer to design a foundation that meets local building codes and addresses the specific load requirements of your pole barn.

3. Foundation Preparation: Clear the site, excavate to the specified depth, and ensure proper drainage is established around the foundation perimeter.

4. Installation and Reinforcement: Install the chosen foundation system, incorporating reinforcement bars or other strengthening elements as directed by the engineer.

5. Concrete Pouring and Curing: Pour the concrete for piers, ICFs, or slabs, allowing adequate time for curing and achieving full strength.

6. Final Inspection and Approval: Obtain final inspection and approval from the building department to ensure compliance with local regulations.

Considerations for Long-Term Performance:

Drainage and Waterproofing: Implement a comprehensive drainage system around the foundation to divert rainwater and prevent moisture accumulation. Utilize waterproofing materials to seal any potential entry points for water.

Pest Control: Consider using pest-resistant materials and techniques during foundation construction. Install screens or barriers to prevent entry and implement regular pest control measures.

Maintenance and Monitoring: Regular inspections and maintenance are crucial for identifying potential problems early. Address any cracks, settlements, or water damage promptly to prevent escalation.

Conclusion:

Constructing a pole barn with a custom foundation is an investment in long-term stability and functionality. By meticulously planning, engaging qualified professionals, and implementing best practices, you can ensure your barn stands the test of time, providing a robust and reliable structure for years to come. Remember, a well-designed and executed foundation is the cornerstone of a strong and enduring pole barn.

No comments:

Post a Comment